At Fluid Valve Manufacturing Company, we specialize in producing top-notch Wafer Type Check Valves. Our Wafer Type Check Valve manufacturer process adheres to the highest industry standards, ensuring the valves meet stringent quality and performance criteria. These valves are designed for optimal flow control and offer seamless installation between flanges, making them a popular choice across various industries. Our expertise extends beyond Wafer Type Check Valves. We are also renowned for manufacturing Butterfly Valves, Dual Plate Check Valves, Knife Gate Valves and other fluid control solutions. This diverse product range allows us to cater to a wide spectrum of industries, offering customized solutions that meet specific application requirements.

| Body | Cl/ MS/ SGI / WCB | CF8 | CF8M |

| Disc | MS / WCB / CF8 / CF8M | CF8 | CF8M |

| Seat | Nitrite / EPDM / Silicon / Viton / PTFE | ||

| Spring | SS316 | ||

| WAFER CHECK VALVE | ||

| Size | Cracking Pressure mbar |

Cracking Pressure mbar —> |

| 40 | 17.5 | 1.05 |

| 50 | 12.4 | 0.75 |

| 65 | 8.8 | 0.53 |

| 80 | 10.4 | 0.62 |

| 100 | 9.6 | 0.58 |

| 125 | 10.5 | 0.63 |

| 150 | 10.8 | 0.65 |

| 200 | 15.3 | 0.92 |

| 250 | 16.9 | 1.02 |

| 300 | 20.7 | 1.24 |

| 350 | 17.5 | 1.05 |

| 400 | 19.1 | 1.15 |

| 450 | 19.9 | 1.19 |

| 500 | 16.6 | 1 |

| 600 | 23.9 | 1.43 |

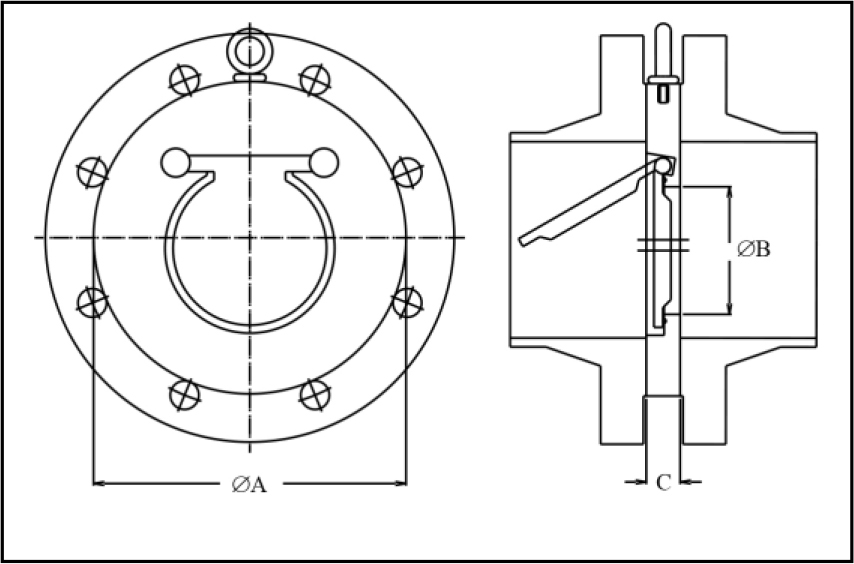

All Dimensions are in mm

SIZES |

40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | |

| OA | # 150 (PN25) |

85 | 105 | 124 | 137 | 175 | 197 | 222 | 279 | 340 | 410 | 451 | 514 | 549 | 606 | 717 |

# 300 (PN40) |

95 | 111 | 130 | 149 | 180 | 216 | 250 | 307 | 362 | 422 | 486 | 540 | 597 | 654 | 775 | |

PN 10 |

94 | 109 | 129 | 144 | 164 | 194 | 220 | 275 | 330 | 380 | 440 | 491 | 541 | 596 | 698 | |

PN 16 |

94 | 109 | 129 | 144 | 164 | 194 | 220 | 275 | 331 | 386 | 446 | 498 | 558 | 620 | 737 | |

BS 10TD |

85 | 98 | 111 | 130 | 162 | 194 | 219 | 276 | 336 | 386 | 448 | 498 | 562 | 619 | 730 | |

BS 10TE |

85 | 98 | 111 | 130 | 162 | 194 | 216 | 273 | 336 | 384 | 448 | 498 | 562 | 619 | 730 | |

| 0B |

|

20 | 30 | 40 | 52 | 71.5 | 93 | 114 | 157 | 195 | 240 | 270 | 311 | 361 | 392 | 480 |

| C | #150 |

19 | 19 | 19 | 19 | 19 | 19 | 19 | 29 | 29 | 38 | 44 | 51 | 60 | 64 | 70 |

As a reputable Wafer Type Check Valve manufacturer, we prioritize quality assurance throughout our manufacturing process. Our valves undergo rigorous testing, including pressure testing, leakage testing, and material analysis, to guarantee their performance and longevity. We continuously invest in research and development to stay at the forefront of valve technology, ensuring that our products meet the evolving needs of industries worldwide. While we offer a wide range of standard valves, we also excel in providing tailor-made solutions to meet unique specifications. Our team of experienced engineers collaborates closely with clients to design and manufacture valves that precisely match their requirements, ensuring optimal performance and cost-efficiency.

Fluid Valve Manufacturing Company is your trusted partner for high-quality fluid control solutions. As a leading Wafer Type Check Valve manufacturer, we have earned the trust of industries worldwide through our commitment to excellence, innovation and customer satisfaction. Whether you require Wafer Type Check Valves or any other fluid control solution, we have the expertise and capabilities to deliver the best-in-class products that meet your needs.

Tags: Wafer Type Check Valve Exporter in India, Wafer Type Check Valve Exporter in Russia, Butterfly Valve Exporter in Bahrain, Butterfly Valve Exporter Iran, Butterfly Valve Exporter Iraq, Butterfly Valve Exporter Kuwait, Butterfly Valve Exporter Oman, Butterfly Valve Exporter Qatar, Butterfly Valve Exporter Saudi Arabia, Butterfly Valve Exporter Yemen, Butterfly Valve Exporter UAE.